Technology Domains

Assistive

Technologies

Assistive Technology (AT) products are an area of core expertise for Encore

Research

Embedded

Systems

At Encore Research, we have over 20 years of experience in developing embedded systems with a wide range of complexity

Mechatronics and

Motion Solutions

Having developed highly complex systems involving thousands of microscopic moving parts, mechatronics is one of our specialties

Artificial Intelligence and

Machine Learning

We have over 10 years of experience in the application of AI and ML techniques in solving complex problems

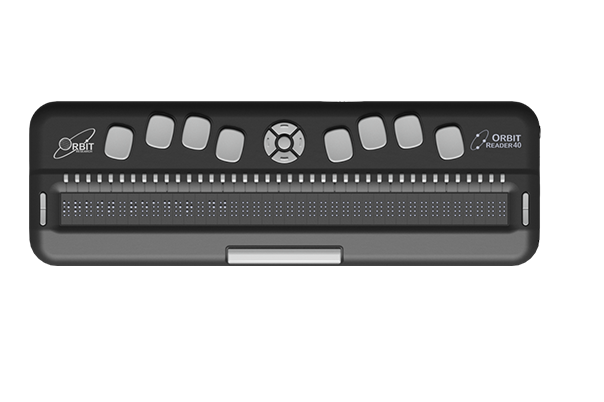

affordable Braille

Keyboard

Braille Display in the

world, with the

highest quality of

braille

affordable 40-cell

Braille Display,

offering Signage-

quality braille

only Tactile Graphic

Display with

multi-level pins

only Handheld Talking

Graphing Calculator

only multi-line Talking

Scientific Calculator

compact and

affordable money

identifier